Hi guys...

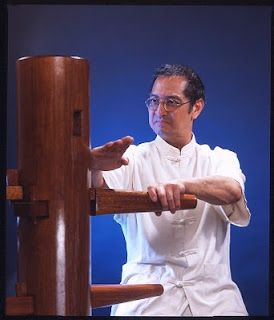

I'm in the process of building my own dummy...

I've seen both round and square dummy arms (I'm taling about the part that sticks OUT of the dummy, not the part that's inserted).

I'm not quite sure what the advantages and disadvantages are of square and round arms...

What do you think?

Round and tapered from thick at the base to thinner at the ends. Definitely. The only WC/WT/VT dummies that have square-ish arms are sort of square at the base near the dummy body, but rounded as you move outward away from the trunk. Many of the classic dummy movements involve circling the hands around the dummy arms, so rounded arms are essential.

Now if you are making your own dummy and do not have access to a lathe, you can taper and round the arms the old-fashioned way with a plane or spoke-shave. Most Chinese dummy trunks were rounded by hand too. A square beam would be trimmed by taking off the corners with a saw, creating an octagonal beam. This would then be rounded by hand with a plane and sander. In fact my old Ku-Sang dummy circa the mid 80's still has a vaguely octagonal shape, which although not visually apparent, can be felt when doing the form. It actually works quite well since the faint, residual "faceting" aligns pretty well with the angles you strike it from.

As for the arms, I once made a set of dummy arms using the center portion of three old wooden baseball bats I got for next to nothing at a thrift store. I used a bandsaw to cut the sides of the fat end down to make the tenons (square pegs). The tenons were too short, so I cut them off at an angle and spliced them to a good piece of hardwood to extend them. At the other, skinny end, I just cut off about 6 or 8 inches of the very slender part of each bat handle (the part with the knob) and used a sander to round off the cut end. They came out looking good and worked really well.

Oddly, since I couldn't find a suitable beam for the trunk and as I had access to welding and metal working tools, I chose to make the dummy trunk out of a piece of 10 in. diameter steel tubing I found at a scrap yard. I cut the holes for the tenons and inserted pieces of 2 in. square steel tubing which I welded flush to the surface of the "trunk" to line the sockets for the arms. It worked really well... enough so that I'm surprised nobody makes them like this commercially. Using

aluminum tubing you could create a very light and portable dummy which could be filled with sand and sawdust to add mass as needed. Having some substantial weight really helps.

Anyway, my life changed and I no longer have access to a lot of tools. I finally got my pretty teak wooden dummy and it was all I could do to haul

that around with me over the years. I have no idea where the old metal trunked one with the baseball-bat arms ended up. Probably at the dump by now. Even my wood one almost got thrown out buy my wife at one point! By the time we got settled-in permanently, it was weather damaged, cracking, and missing its leg. Still, I eventually got it fixed up, properly mounted and back in service... at last. So, best of luck. Building your own dummy will be a great experience!