Clark Kent

<B>News Bot</B>

homemade polymer training blades

By blindside - 02-29-2012 04:04 AM

Originally Posted at: FMATalk

====================

Last year I ordered some polymer training blades from a FMA supplier that I really liked. But because I'm a cheap bastard and the training blades weren't exactly inexpensive, I wondered if I could make my own. So a $30 Craigslist "used once" bandsaw, a completely useless $20 router attachment for my dremel, a bunch of paracord, and several purchases of scrap plastics later I think I figured it out, and thought I would share for other DIYers out there.

At this point I have probably made 12 or so training blades and I am pretty happy with their performance.

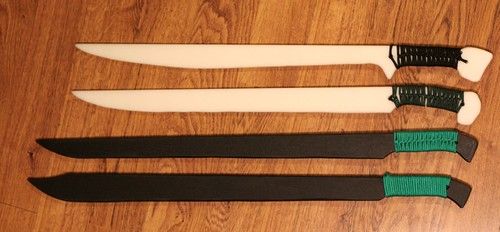

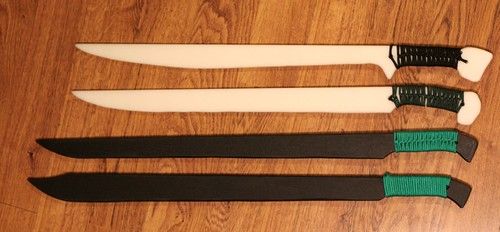

Some examples:

training blades types by wyldbio, on Flickr

training blades sample by wyldbio, on Flickr

Design wise I modeled the blades with a guard off of the Kris Cutlery Pinute. The other blade was very roughly modeled to be a trainer for an antique Itak that I had just won on Ebay. Both blades have overall lengths of 29" or so. Particularly on the pinute trainer you can see the variation that occurs between blades as I played with shapes and hilt angulation.

The longer black blades in the top picture are protoypes for cutlass and messer blades for a friends WMA class. He is providing feedback on what he wants to see in a trainer and we are exploring the potential for add-on steel D or S guards. These blades run 31" or so, both have a 24.5" blade.

The top two white blades were my first two test runs, I started with .375" Nylon 6/6 sheet, and though I find it difficult to cut and shape, I really like the feel when work against another training blade. They are stiff enough that you don't get much vibration when you strike another stick or training blade, so you get a better feel for the blade. I am no longer using the Nylon for training blades mostly because Nylon is expensive, and as previously mentioned, I am a cheap bastard. Nylon costs for cut-to-order nylon would probably be close to $23 per sword. It would naturally be cheaper to buy a 4x8 sheet, but I don't have $290 +shipping.

I shifted to 1/2 inch HDPE (High Density Polyethelene) for the next set of blades and have been pretty happy with it. It is far cheaper (something like $7/blade) for cut-to-order stock. An additional benefit of the switch is that you can get black HDPE which has the added cool factor versus white/natural for the nylon. The softer HDPE interacts with sticks better than the denser/thinner nylon. Nylon and HDPE trainers don't play well together the nylon puts fairly large dents in the HDPE blades.

The softer HDPE interacts with sticks better than the denser/thinner nylon. Nylon and HDPE trainers don't play well together the nylon puts fairly large dents in the HDPE blades.

The HDPE is not as stiff as nylon and you will feel vibration if you clash sticks and you are not in appropriate edge alignment, this is actually a very useful training tool for beginners, they immediately know when they muff a shot. I am not sure how much longer past 31" HDPE will be a viable plastic stock, I suspect it will get too floppy.

Make sure that the hilt to blade transition is radiused, a sharp angle at this juncture leads to a stress point and a likely break. Our first prototype had a catastrophic failure after just a couple of hits due to us not realizing that. Also make sure you heavily radius the leading edge, having close-to-square edges on the main striking edge will quickly get you serrated training blades (in HDPE, apparently not an issue in nylon.)

The 29" training blades average something like 10.5 ounces, they hit harder than rattan and you would have to use good control if you were going to spar with them. That said, they do allow sparring without the armor jump that the shift from rattan to aluminum long blades requires. I have been very happy with being able to provide my training group with a relatively inexpensive blade trainer. I hope this post helps you all to build your own trainers.

Read More...

------------------------------------

FMATalk.com Post Bot - FMA Feed

By blindside - 02-29-2012 04:04 AM

Originally Posted at: FMATalk

====================

Last year I ordered some polymer training blades from a FMA supplier that I really liked. But because I'm a cheap bastard and the training blades weren't exactly inexpensive, I wondered if I could make my own. So a $30 Craigslist "used once" bandsaw, a completely useless $20 router attachment for my dremel, a bunch of paracord, and several purchases of scrap plastics later I think I figured it out, and thought I would share for other DIYers out there.

At this point I have probably made 12 or so training blades and I am pretty happy with their performance.

Some examples:

training blades types by wyldbio, on Flickr

training blades sample by wyldbio, on Flickr

Design wise I modeled the blades with a guard off of the Kris Cutlery Pinute. The other blade was very roughly modeled to be a trainer for an antique Itak that I had just won on Ebay. Both blades have overall lengths of 29" or so. Particularly on the pinute trainer you can see the variation that occurs between blades as I played with shapes and hilt angulation.

The longer black blades in the top picture are protoypes for cutlass and messer blades for a friends WMA class. He is providing feedback on what he wants to see in a trainer and we are exploring the potential for add-on steel D or S guards. These blades run 31" or so, both have a 24.5" blade.

The top two white blades were my first two test runs, I started with .375" Nylon 6/6 sheet, and though I find it difficult to cut and shape, I really like the feel when work against another training blade. They are stiff enough that you don't get much vibration when you strike another stick or training blade, so you get a better feel for the blade. I am no longer using the Nylon for training blades mostly because Nylon is expensive, and as previously mentioned, I am a cheap bastard. Nylon costs for cut-to-order nylon would probably be close to $23 per sword. It would naturally be cheaper to buy a 4x8 sheet, but I don't have $290 +shipping.

I shifted to 1/2 inch HDPE (High Density Polyethelene) for the next set of blades and have been pretty happy with it. It is far cheaper (something like $7/blade) for cut-to-order stock. An additional benefit of the switch is that you can get black HDPE which has the added cool factor versus white/natural for the nylon.

The HDPE is not as stiff as nylon and you will feel vibration if you clash sticks and you are not in appropriate edge alignment, this is actually a very useful training tool for beginners, they immediately know when they muff a shot. I am not sure how much longer past 31" HDPE will be a viable plastic stock, I suspect it will get too floppy.

Make sure that the hilt to blade transition is radiused, a sharp angle at this juncture leads to a stress point and a likely break. Our first prototype had a catastrophic failure after just a couple of hits due to us not realizing that. Also make sure you heavily radius the leading edge, having close-to-square edges on the main striking edge will quickly get you serrated training blades (in HDPE, apparently not an issue in nylon.)

The 29" training blades average something like 10.5 ounces, they hit harder than rattan and you would have to use good control if you were going to spar with them. That said, they do allow sparring without the armor jump that the shift from rattan to aluminum long blades requires. I have been very happy with being able to provide my training group with a relatively inexpensive blade trainer. I hope this post helps you all to build your own trainers.

Read More...

------------------------------------

FMATalk.com Post Bot - FMA Feed